What should I pay attention to when assembling the diaphragm coupling on the shaft?

2022-06-25 08:41

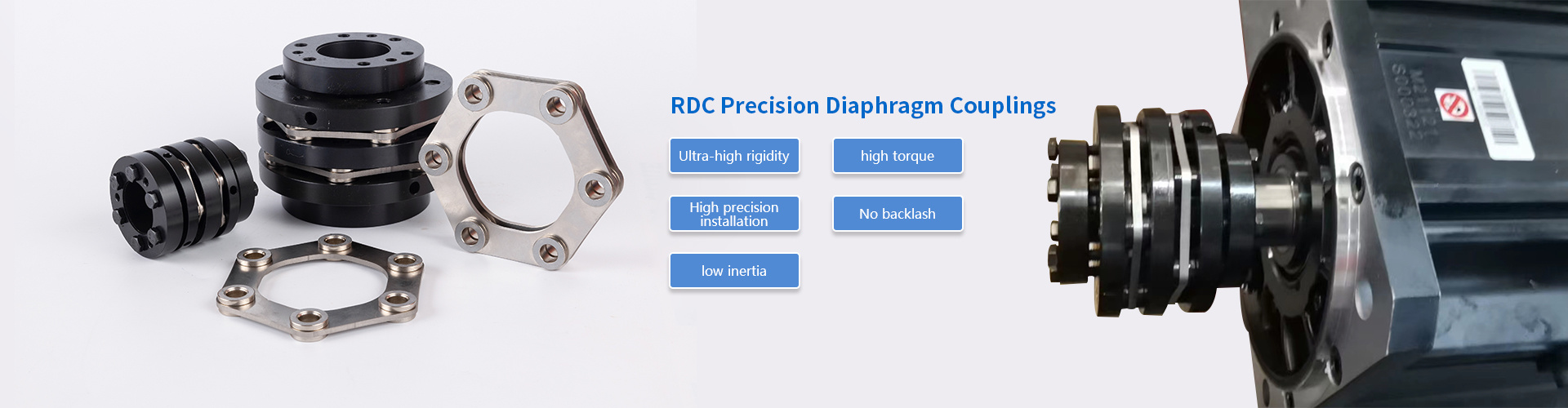

Among the many couplings, the diaphragm coupling is the most common, and most people will choose the diaphragm coupling when choosing a coupling. Although this coupling has a simple structure, not many parts, and a relatively small radial size, it does not require lubrication, and the elastic element has a relatively high bearing capacity under compression. When we replace the diaphragm coupling, we need to move the half coupling axially, otherwise the replacement may fail and the position will be offset.

After the diaphragm coupling is assembled on the shaft, the verticality and coaxiality of the coupling and the shaft need to be carefully checked. Generally, two dial indicators are set on the end face and outer circle of the diaphragm coupling. When the crankshaft rotates, observe the full runout of the diaphragm coupling, including the end face runout and radial runout, and then determine the coupling. the perpendicularity and coaxiality of the actuator to the shaft.

Note: Different speeds and different types of couplings have different requirements for runout. After the coupling is assembled on the shaft, the deviation value of the full runout of the coupling must be within the tolerance range required by the design. This is the diaphragm One of the main technical requirements for coupling assembly.

Kunshan Haozong Transmission Technology Co., Ltd.

Contact: Manager Liu 13372152786 (WeChat)

Email: liu@hz-coupling.com

Address: Room A5-304, No. 18 Jinxing Road, Huaqiao Town, Kunshan City, Jiangsu Province

Scan the mobile website