HSC-B Elastic Coupling

Category:

HSC-B Elastic Coupling

- Product Description

-

Product Features

● It is suitable for the connection of engineering machinery, construction machinery transmission system, diesel engine and hydraulic pump.

● Adopt elastic fiberglass materials, with strong absorption of vibration and impact.

● Oil, heat and cold resistance (-40 ℃ to 150 ℃).

● Easy to install and adjustable axial dimension.

● Splined hub with locking device can reduce spline abrasion.

● Reinforced large rectangular tooth connection is adopted for glass fiber disc and shaft sleeve, resistant to wear and deformation and long service life.

Typical Applications

Excavators, rollers, cranes, Grader, pavers, Concrete mixer, concrete pumps, concrete cutters, road chisels, garbage dumpers, etc.

Selection calculation formula

TKN=TAN*K

Where TAN: rated torque of the engine

K: Working coefficient, 1.2-2 depending on operating conditionsStructural composition

Shaft sleeve: Made of high-grade steel material, sturdy and reliable.

Flywheel connecting plate: Made of elastic fiberglass material, it has extremely high impact resistance and vibration absorption ability

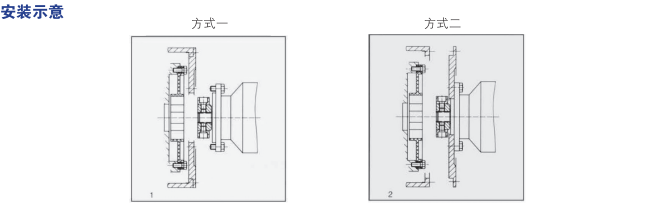

In most cases, the diameter of the hub star is smaller than the center positioning diameter of the pump flange, meaning that the "hub star" passes through a hole in the flange that connects the pump to the flywheel housing. The diameter of the hub star component is always slightly smaller than the nominal size of the coupling, for example, the rotation diameter of the hub star component in HSC-B-100 is less than 100mm. If the diameter is 100 millimeters or 4 inches or larger, it will pass through the hole on the pump mounting plate. In this case, the installation can be carried out according to the installation diagram method one.

1. Fix the coupling flange to the flywheel with bolts.

2. Fix the pump mounting plate to the flywheel housing with bolts.

3. Install the coupling onto the pump shaft and secure it.

4. Provide the pump upwards to engage the coupling and pump in the pump mounting plate.

For occasional situations where the diameter of the "hub star" is greater than the hole diameter in the pump mounting plate, installation should be carried out according to the installation diagram method 2.

1. Fix the coupling flange to the flywheel with bolts.

2. Fix the pump mounting plate to the pump with bolts.

3. Install the coupling hub onto the pump shaft and secure it.

4. Provide the pump and mounting plate upwards to connect the coupling and position the pump mounting plate in the flywheel housing. Secure the entire assembly to the flywheel housing with bolts.