ETP-EXPRESS Tightening Sleeve

Category:

Hydraulic Tightening Sleeve

- Product Description

-

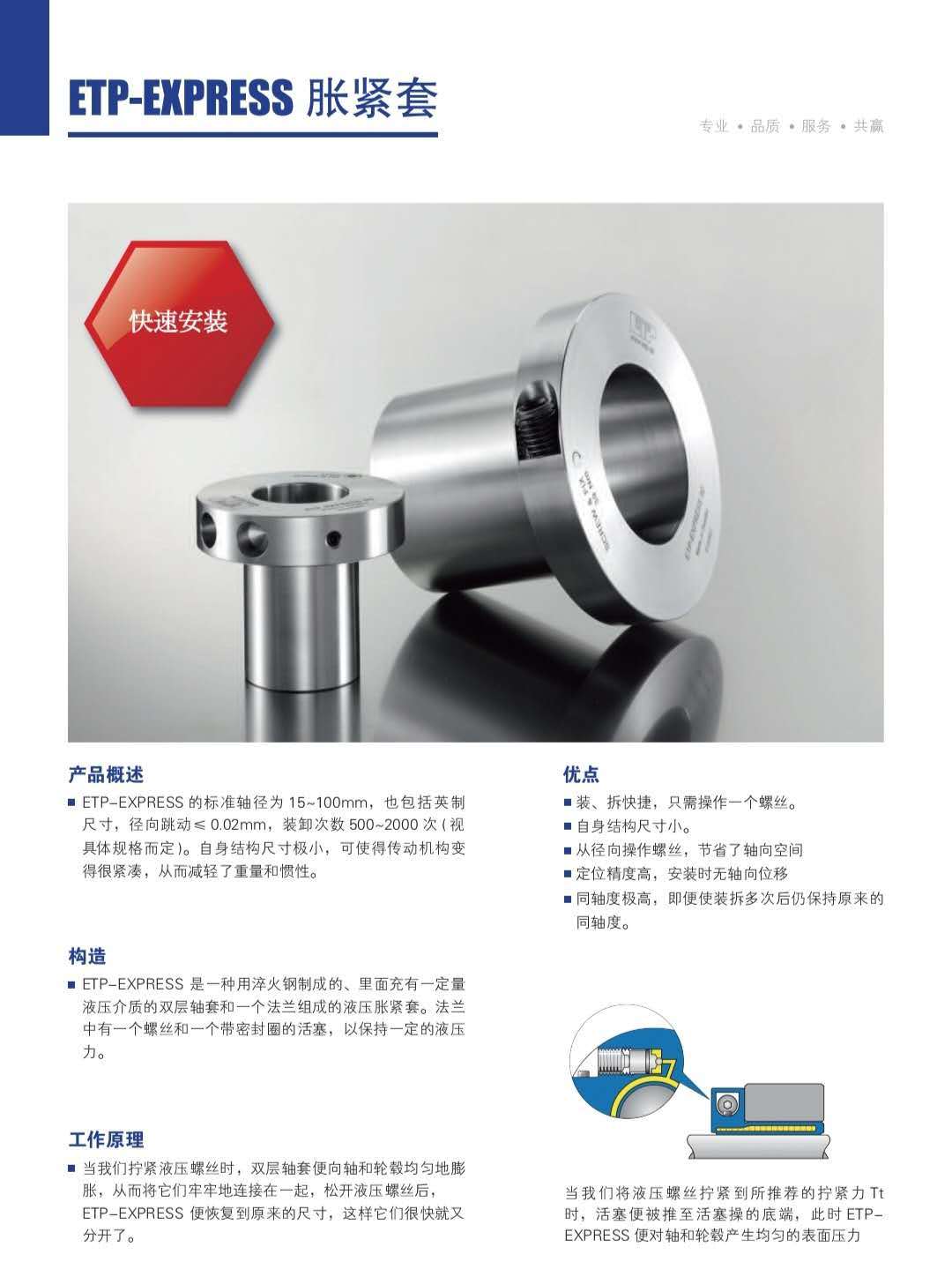

ETP-EXPRESS hydraulic tightening sleeve can be installed with only one screw, which is very suitable for those mechanisms that need to quickly and accurately position the hub repeatedly. It is tightened by screws from the radial direction, so there is no need to leave operating space for installing tools in the axial direction. Other parts can be arranged one by one in the axial direction until they are against the flange. The structural size of ETP-ESPRESS is so small that it allows for a compact design of the entire mechanism.

The standard shaft diameter of ETP-EXPRESS is 15-100MM (including inch size), the runout is ≤0.02mm, and loading and unloading frequency is 500-20000 times (depend on the specifications). Small structural size allows for compact transmission mechanism to reduce the weight and inertia.

Structure: ETP-EXPRESS is a hydraulic coupling made of hardened steel, which consists of a double-layer shaft sleeve filled with a certain amount of hydraulic medium and a flange. The flange is designed with a screw and a piston with a sealing ring to maintain a certain hydraulic pressure.

Operating Principle: when we tighten the hydraulic screw, the double-layer shaft sleeve will expand evenly towards the shaft and the hub to closely connect with each other; After loosening the hydraulic screw, ETP-EXPRESS will return to its origin size to separate from each other.

Advantages:

● Only one screw required for installing and removal, easy and fast.

● Small structural size.

● It saves axial space when operating the screws from the radial direction.

● High positioning precision and no axial displacement when installing.

● High coaxiality, remaining unchanged even after installing and removal for many times.