The working principle of the hydraulic locking sleeve of the machine tool spindle

2022-08-03 15:46

In the machining process of mechanical parts, such as a five-axis machining center, different parts often have multi-angle planes, so the cutting tool not only needs to be able to achieve fixed-angle machining but also multi-angle machining. Therefore, a corresponding mechanism is required to realize the locking function of positioning and angling. Hydraulic locking bushings are very suitable. Hydraulic locking bushings have many advantages such as large locking area, large locking torque, stable and reliable locking state, etc., so they are very suitable for the locking of machine tool spindles.

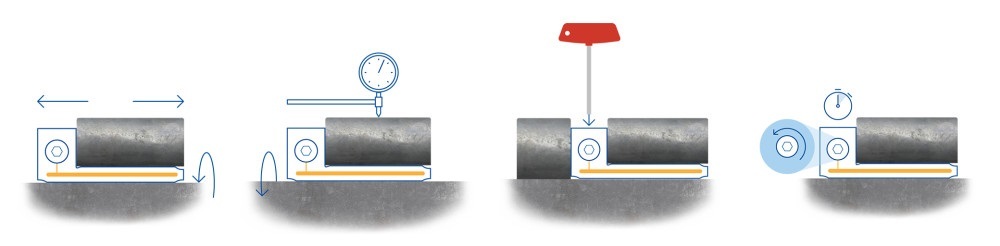

The outer wall of the hydraulic locking shaft sleeve is in contact with the body to form an annular closed oil cavity, and there are annular sealing rings at both ends of the shaft sleeve to prevent hydraulic pressure leakage and oil leakage. There is a gap between the inner wall of the shaft sleeve and the rotary shaft, which can ensure the normal rotation of the main shaft. When the main shaft needs to be locked and the hydraulic rotary shaft needs to be locked, the hydraulic system provides hydraulic oil, and the hydraulic locking sleeve is elastically deformed under the action of the high-pressure oil to hold the main shaft tightly and generate tangential friction to prevent Spindle rotates. Specifically as shown in the figure below:

When the main shaft does not need to be locked, the hydraulic system releases the pressure, the hydraulic locking shaft sleeve recovers the deformation, returns to the original clearance state, and the main shaft can rotate again. Because the hydraulic locking bushing locks the spindle is completely symmetrical, so the spindle is evenly stressed, the locking effect is good, and the locking area is large and the locking effect is good, which can ensure the machining accuracy of the machine tool and can realize locking at any angle. tight.

Kunshan Haozong Transmission Technology Co., Ltd.

Contact: Manager Liu 13372152786 (WeChat)

Email: liu@hz-coupling.com

Address: Room A5-304, No. 18 Jinxing Road, Huaqiao Town, Kunshan City, Jiangsu Province

Scan the mobile website