The role of the diaphragm coupling as a coupling device

2022-06-25 08:50

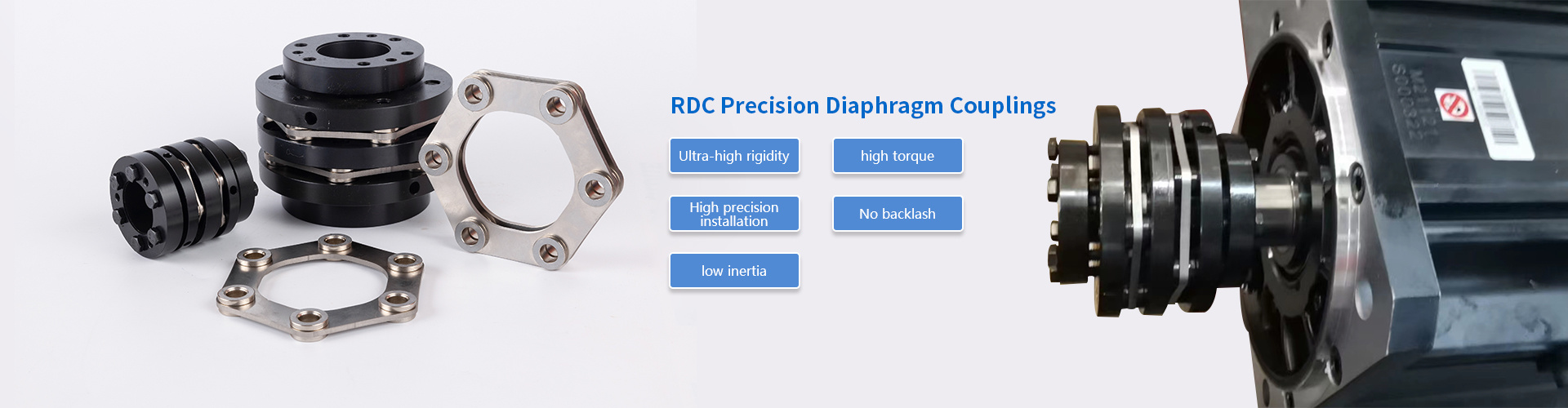

Diaphragm couplings are used to connect two shafts and transmit torque to parts, and sometimes also serve as overload safety protection. The coupling is a fixed connection device, which cannot be disengaged at will when the machine is running normally, and must be stopped to disengage. Diaphragm couplings are used to connect shafts to transmit motion and torque; to compensate for the relative displacement of the two connected shafts; manufacturing machine installation errors, deformation, temperature changes - strict alignment cannot be guaranteed; can be used as a safety device; Vibration absorption and buffering.

The coupling is used to connect the two shafts together. The two shafts cannot be separated when the machine is running. The two shafts can only be separated after the machine is stopped and the connection is disassembled. The two shafts connected by the coupling, due to manufacturing and installation errors, deformation after loading, and the influence of temperature changes, will cause changes in the relative positions of the two shafts, which often cannot guarantee strict alignment. According to whether the coupling has elastic elements, whether it has the ability to compensate for various relative displacements, that is, whether the coupling function can be maintained under the condition of relative displacement and the purpose of the coupling, the coupling can be divided into rigid couplings. Flexible couplings and safety couplings.

The main types and characteristics of couplings and their role in the transmission system in the action category. Rigid couplings can only transmit motion and torque, and do not have other functions including flange couplings, sleeve couplings, clamps Shell couplings, etc.; flexible couplings without elastic elements, not only can transmit motion and torque, but also have different degrees of axial, radial, and angular compensation performance, including gear couplings, universal joints couplings, chain couplings, slider couplings, etc.; flexible couplings with elastic elements, which can transmit motion and torque; have different degrees of axial, radial, and angular compensation performance.

The diaphragm coupling also has different degrees of vibration reduction and buffering, improving the working performance of the transmission system, including various non-metallic elastic element flexible couplings and metal elastic element flexible couplings, various elastic couplings The structure is different, the difference is large, and the role in the transmission system is also different. Safe transmission of motion and torque, overload safety protection. The flexible safety coupling also has different degrees of compensation performance, including pin type, friction type, magnetic powder type, centrifugal type, hydraulic type and other safety couplings. Diaphragm couplings are suitable for servo motors and stepper motors.