The compressive stress of the coupling in the operation of the machine

2022-06-25 08:49

The compressive stress of the coupling in the operation of the machine

The use and selection of the coupling are determined by the force. The force is different, and the model size is also different. Generally, in order to optimize the use efficiency of the coupling, a mechanical model is established to analyze the effect of various forces and moments, so as to achieve the main point of stress. Optimize and design various couplings to achieve better results. In order to establish the mechanical model of the half-coupling, it is assumed that the serpentine spring is still in contact with the adjacent teeth after deformation, and each tooth is subjected to the same force. The cross-sectional size of the snake spring is much smaller than the radius of the cylinder where it is located, so the calculation is approximated by a plane problem.

The purpose of using the spring coupling in the mechanical system is to allow it to withstand various misalignments during operation. Therefore, the half coupling should mainly be subjected to the following forces and moments during operation. Under the action of torque, the serpentine spring acts on the extrusion stress of the half-coupling; because it is a high-speed serpentine spring coupling, the half-coupling will generate a large centrifugal force; under the action of the torque, the serpentine spring acts on the half-coupling Shear force at the tooth root of the coupling; radial and tangential force during rotation; bending moment during angular offset, etc. During operation, the stress caused by the first three forces belongs to the category of static force, and the stress caused by the last two forces belongs to the category of dynamic force, and changes with each revolution of the shaft.

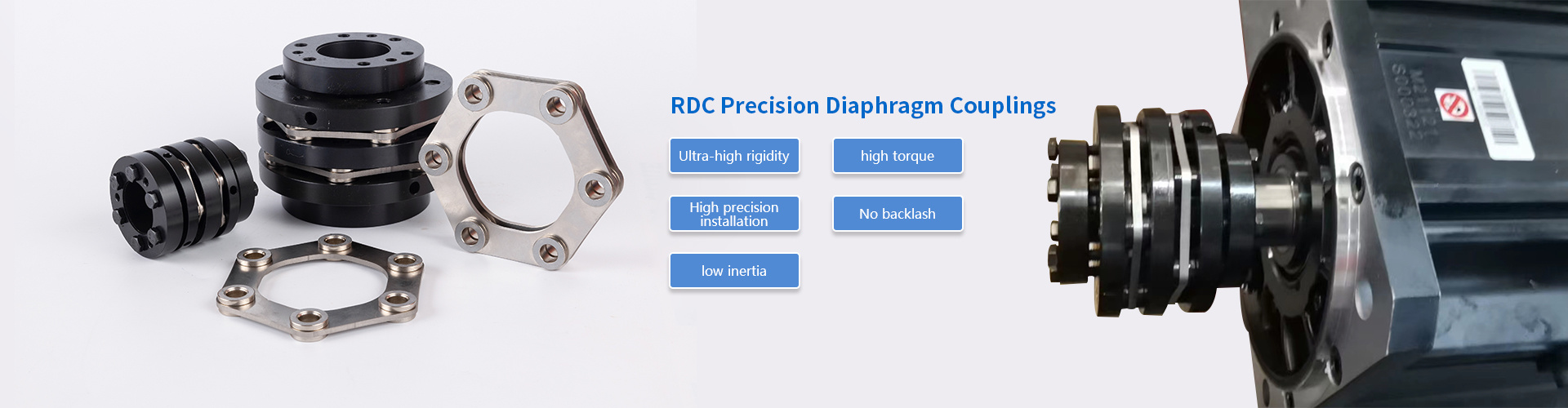

During the analysis, it is found that the main stress concentrated on the half coupling is generated by centrifugal force, extrusion force and shear force at the tooth root, so these three forces are mainly analyzed in the following analysis. The model is simplified as a combination of spur gear and serpentine spring. During the force analysis, under the action of torque, the tooth flank of the half coupling will be subjected to compressive stress, and the tooth root will be subjected to shear force. When designing a diaphragm coupling, the designer must understand the stress of each part of the coupling when it is working - the internal characteristics of the coupling. Various stiffnesses of couplings—external characteristics of couplings. For the stress index, it is only used as the reliability basis for the coupling when it is working, and it belongs to the designer. These data do not necessarily have to be published to the user.

For the external characteristics of the coupling, not only the designer should master it, but also publish it to the user, because it will directly affect the reliable and safe operation of the equipment connected to the coupling. In some occasions, such as requiring small angular deformation stiffness or axial deformation stiffness, the external characteristics of the coupling are crucial. The stiffness of the coupling is composed of the stiffness of the parts that make up the coupling and participate in the deformation, but for the general parts of the coupling, such as torsion bolts, flanges and intermediate shafts, their deformation can be obtained from the general technical data. get. Torsional stiffness and radial stiffness are great. In particular, the radial stiffness is close to that of a general rolling bearing, while the axial stiffness and angular stiffness are much smaller, which is the most prominent feature of the diaphragm coupling.