Rigid Coupling Considerations

2022-06-25 08:48

Precautions for use

Rigid coupling is a coupling produced by using a precision lathe and processing two axes at the same time (same hole diameter or different hole diameter can be used). The clamping type is cut and grooved after removing the internal strain force by heat treatment, and the concentric accuracy is maintained. But even so, special care must be taken to maintain concentric high precision during assembly and to keep axis braking as controlled as possible.

●Inspection method of radial deviation and angular deviation in assembled state (refer to Fig. 1)

Place the shaft (1) of the assembled assembly on the V-block, turn it slowly, and measure the peripheral deflection of the shaft (2) with the test indicator.

For example: when the deflection at point A is 0.04, the radial deflection is 0.02.

Then, if the peripheral skew value of point B (the position away from point L of A) is 0.16 and L is 100, then the angular deviation a is:

●Precautions for assembly (set screw type)

Refer to (Figure 2)

●Please wash the fitting part and remove the dirt

●Please turn the shaft or coupling lightly, and screw in the 2 set screws inclined left and right alternately and evenly, so that the shaft is firmly fixed on the C ground.

●Please keep the shaft (1) and the shaft (2) in a straight line when assembling, and there is no angular deviation.

If it is tightened with angular misalignment like (Fig. 3), it cannot be corrected at all.

●When the shaft is made of soft plastic or aluminum alloy, do not forcefully tighten the positioning screw. Otherwise, the shaft will bend and deform, resulting in angular misalignment.

●Precautions for assembly (clamping screw type)

Refer to (Figure 4)

●Please wash the fitting part and remove the dirt

●Please tighten the tightening screw little by little while turning the shaft or the coupling lightly.

The diameter of the coupling is consistent with the outer circumference of the shaft, and the radial deviation e is 0. This is the characteristic of clamping type couplings.

●Please keep the shaft (1) and the shaft (2) in a straight line when assembling, and there is no angular deviation.

If it is tightened with angular misalignment like (Fig. 5), it cannot be corrected at all.

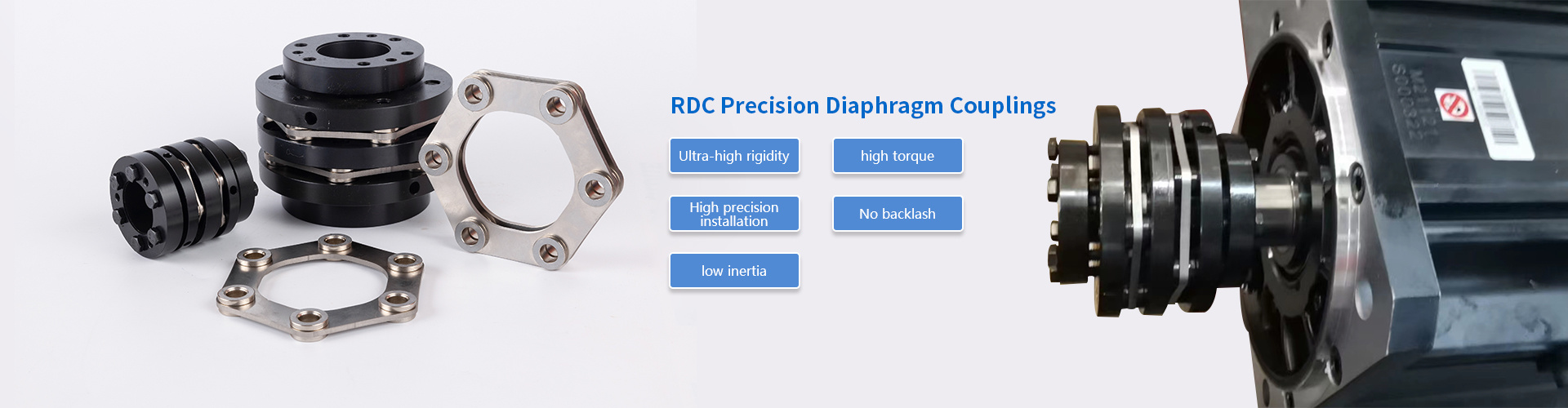

Diaphragm coupling

●Zero backlash

●Smooth rotary transmission

●Variety and wide range of uses

Diaphragm coupling is an elastic coupling that uses the elastic deformation of the diaphragm to compensate for radial and angular deviations. There are two types of single diaphragm and double diaphragm. In order to prevent unexpected damage to the system, the correct product must be selected according to the actual situation. (Refer to the picture below)

Plate properties

●Polyimide

It is a special engineering plastic with good heat resistance and very stable chemical properties. With high tensile strength and elastic modulus, as the diaphragm of the coupling, its outstanding bending resistance realizes the irreplaceable flexibility of metal.

●Carbon fiber FRP

It is a material that impregnates carbon fiber fabric in resin to make it hard. Among the materials on the market, it has a high strength ratio and modulus ratio, and its mechanical properties are very good, with small creep and fatigue resistance. Up to 3 to 7 times that of aluminum alloys. As the diaphragm of the coupling, it has high torsional rigidity and transmission torque, and at the same time, the balance performance is good, and the bending caused by the radial and angular deviation will not cause fatigue damage.

●Stainless steel diaphragm

A stainless steel sheet that has been specially given spring properties by heat treatment is used. The tensile strength is the highest among the three, and as the diaphragm of the coupling, it is a type with high rigidity and high torque. On the other hand, in particular, the allowable amount of radial deviation is the smallest, so it is necessary to pay attention to the inconsistency of the shaft center in order to facilitate assembly.